Tag labels for labeling with warning- and consumer information

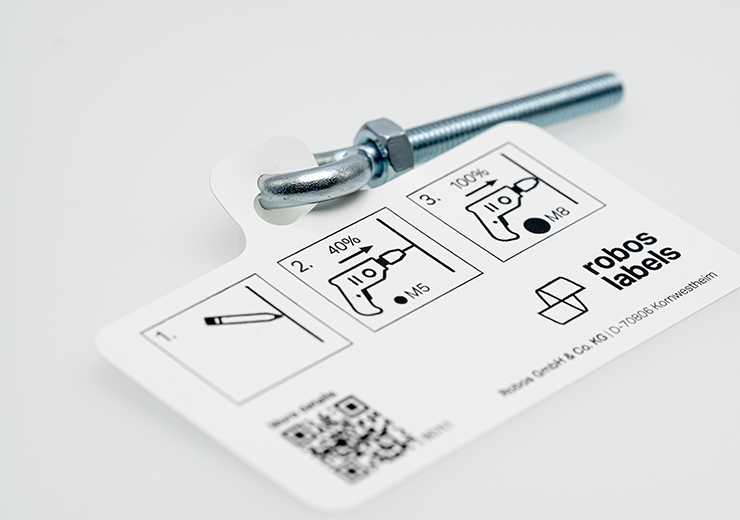

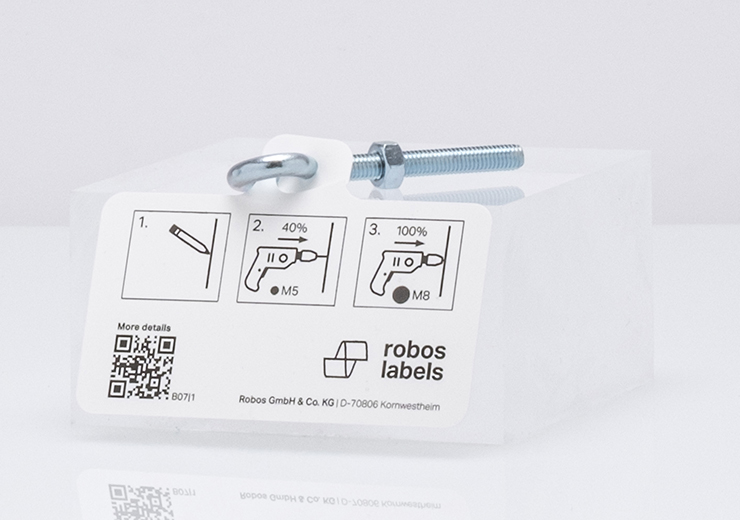

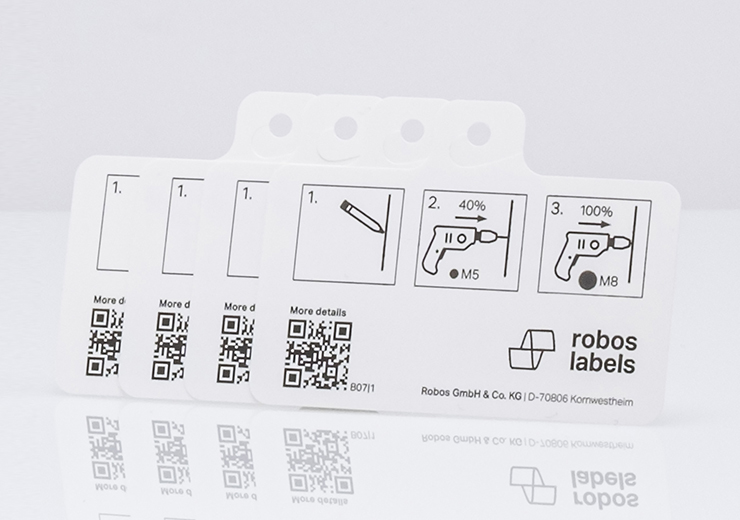

The tag labels offer a hanging tab or will be hung onto the product or part with help of a cut-out or punching. An attaching with adhesive does not take place here. The type of a hanging tab always depends on the customer requirement and the part to be labeled. Here cut-outs or punching or special forms of slots come into action to allow for an adhesive-free and detachable application of the label and the safe labeling with warning-, processing-, and consumer information on the product. The primary tasks of the tag labels are management, controlling and tracking of materials and products in the area of intralogistics by coding.

The key features of tag labels

- High resistance for outdoor applications and in the area of chemicals and solvents

- High resistance against mechanical abrasion and dirt, humidity and UV insolation

- Secure application and durability of the labels also on difficult spots of a product

- Optimization of the processes by automation of material- and product flow

- Numerous special materials by Avery, 3M, Flexcon, and Tesa available from stock

- Tag labels in individual formats and special forms

Functions and advantages – precisely tailored to your requirements for the labeling

The tag labels offer the best possible flexibility and will be adjusted individually to the customer’s requirements. This happens by the combination of suitable special materials and premium processing lines.

The labels can be retrieved directly at robos-labels, by that the storage and the management of numerous labels may be reduced or partially dropped.

Some of the products to be labeled are still hot when the labels must be hung on. The labels withstand there requirements without any problems. Our upscale and accurate processing with most modern die-cutting technologies guarantees the highest precision and reliability for the label application.

Frequently Asked Questions

Industrial applications of tag labels

The typical labeling products in the area of tag labels are barcode labels, rating plates as well as caution- and warning labels. These labels can be applied for example in the following branches and areas:

- Mechanical engineering (engines, machines and machine tools)

- Electric tools (tools, home appliances, office machines etc.)

- Car manufacturing (OEMs, supplier)

- Vehicle construction (public transport, freight transport, ships and train construction)

- Medical products (active and non-active products)

- Chemical industry (hazmat containers, gas cylinders, pipes, conductions, and container labeling)

Individual features of tag labels

The tag labels are extremely robust and there are various possibilities for the attachment to the product. The tag labels can be removed fast without residue when their operational purpose is fulfilled and the labeling is no longer required. Additionally, the tag labels can be equipped with perforations to remove individual parts of the labeling easily and without any tool, e.g. for the documentation purpose of processing steps.

Technical key data of our tag labels

- Temperature resistance from +180° C (256° F) C to -50° C (-58° F)

- UV and weather resistant foils up to max. 10 years

- Very thin (min. 6µ) as well as very thick (175µ) combinations of foils possible

- High-performance materials made of acrylate-foil, polyimide foil, aluminum foil, and polyester (PET)

- Solid-colored materials are possible (pantone or RAL colors)

- Durable products with variable data like encoding, barcodes etc.

- Foil features are stable, weather-resistant and tear-proof

Certification of our tag labels

As a manufacturer robos-labels has a wide range of already approved and certified labeling solutions. When additional customized licenses are required, we can take on the approval- and certification process if desired.

We already meet the following standards and regulations with our raw materials:

- UL969A:2020 Standard for Marking and Labeling Systems – Flag Labels, Flag Tags, Wrap-Around-Labels and Related Products

- UL817 Safety cord sets and power supply cords

- UL2238 Cable assemblies and fittings for industrial control and signal distribution

- UL94 Flammability of plastic materials for parts in devices and appliances (UL VTM-0 strictest classification)

- FMVSS 302 Evaluation of the flammability of interior materials (flammability/burn rate)

- REACH, RoHS and IMDS conformity

- ADR 2021 Ordinance on the transport of dangerous goods by road, rail and inland waterways (GGVSEB)

- CLP Regulation (Classification, Labelling and Packaging, in accordance with EC No. 1272/2008)

- BS 5609 Label resistance to saline sea water

- DIN EN ISO 11683:1997-11 Packaging – Tactile warnings of danger – Requirements

- FDA 175.105 INDIRECT FOOD ADDITIVES: ADHESIVES AND COMPONENTS OF COATINGS