In the year 2022 the CO2 emission could be reduced by 20 tons

The awareness of the environment is meanwhile present in all areas. Either drinking straws and pasta packaging made of paper, reusable packaging in the food service or bags and clothing made from recycled material – there is still plenty of potential to save resources. Also during the production process of labels we continuously minimize unnecessary wasting of valuable materials for e.g. an intelligent distribution of benefits or arrangement, the flexible use of correct material widths or by a processing with most modern laser die-cutting technology. Despite all these measures, however, as the result of manufacturing the die-cutting waste is created, which robos-labels has been homogeneously separating for years, that way it can be made available to a recycling process.

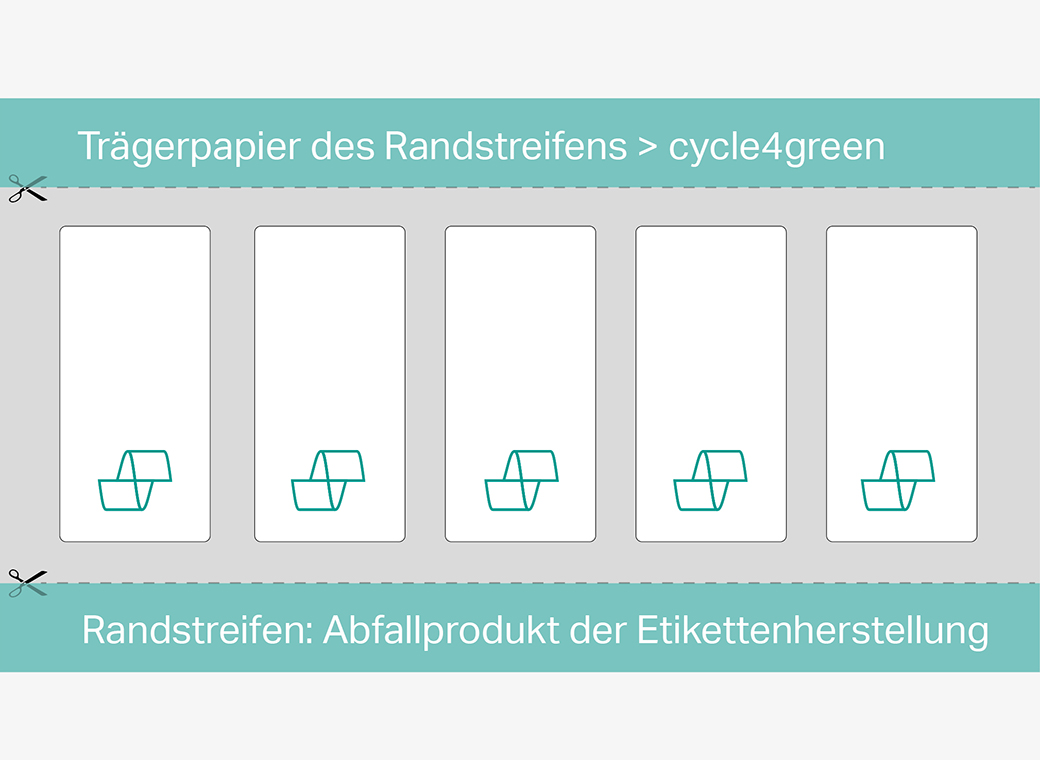

Here it is the release liner of the marginal strips waste – that is the material overlaying on the sides of the roll which remains after the separating. The marginal strips are created when the label panels will be cut on both sides to the required size in the manufacturing. The initial production width of the label panel is necessary because the fiducial marks are located there and the additional width is technically necessary for the separating. The release liner is provided with a silicone layer and remains on the adhesive reverse side of the labels until the application at the customers´. The release liner of the created marginal strips is waste material and can be made available to the recycling.

The marginal strips will be directly vacuumed during the cutting process at the machine and go via a pipe system through a shredder from the production building into a collection container outdoors. There the created scraps will be directly filled into special cardboard boxes and collected by our recycling partner Cycle4Green. They process the marginal paper waste to new products, which is perfect in regard to the environmental aspects and enables a closed recycling circuit. Due to the recycling the use of resources and thus the CO2-emission will be reduced.

Annually there are approx. 360 000 tons of marginal paper waste in the label manufacturing in Europe, from which currently 80% will be deposited and approx. 16% will be thermally utilized. Last year robos-labels sent to recycling 10.5 tons of marginal paper waste from release liner. Another advantage is eliminating disposing costs, whereof eventually robos-labels customers profit as well.

Consequent environmental management

Also in different areas robos-labels takes responsibility for the environment. The company building, which was occupied a few years ago, was built according to the latest energy-saving standards. Almost 20% of the electricity requirement is covered by the own photovoltaic system, the remaining requirement will be covered by 100% ecological electricity and comes from EEG- and TÜV-certified plants. Since the year 2009 robos-labels has completed its management system and is certified in accordance with DIN EN ISO 14001 environmental management.

Cycle4green: Release Liner Recycling

https://www.youtube.com/watch?v=yTR4U-7g5zw&t=4s

FINAT: Release Liner Recycling

https://www.youtube.com/watch?v=TkVbZ_Xoe7k