Serialized and personalized labels for labeling with variable data

The serialized or personalized labels can have a consecutive numeration or encoding, or personal data like names or images. Here every label is unique and does not equal to any other motif. The individual labeling per product, with encrypted encodings, additionally offers numerous possibilities in the automated manufacturing and logistics for the whole life cycle of a product.

Furthermore, often additional matrix codes will be imprinted. They contain comprehensive additional information, which can be retrieved from the stored data banks by scanning of 2D and 3D codes. Additionally, these labels can be subsequently inscribed with further individual data directly at the customer’s site if required.

The labels will be adjusted to the customer-specific requirements and applications and often serve the identification, management, control and tracing of materials and products by encoding.

The main features of the labels with serialization or personalization

- Clear and safe identification of single pieces

- Gapless backtracking of goods and products

- High chemical and mechanical resistance due to protective lacquers and laminates

- High abrasion resistance with suitable thermal transfer ribbons for the thermal transfer printing

- Very high adhesive power of labels also to difficult substrates

- Optimization of processes due to the automation of material and product flow

- Additional safety functions like e.g. security cutouts possible

- Over 500 special materials by Avery, 3M, Flexcon, and Tesa available from stock

- Plain labels in individual formats and special forms

Functions and advantages of serialized labels – precisely tailored to your requirements for the labeling

The serialized and personalized labels will be applied in the inventory, for tracking and tracing, for the control of logistic processes, for the monitoring of distributive chains as well as for applications for the protection against manipulation and forgery. The products can be authenticated also mobile via smartphone.

Individually according to the customer’s wishes the alphanumeric signs, classical one-dimensional or also complex two-dimensional barcodes, 2D data matrix codes will be retrieved from a data bank and printed. With the help of special printing methods we are able to print even smallest 2D codes up to minimal size of 5 x 5 mm (approx. 0.19×0.19 inch) or also multicolored so-called 3D codes. Moreover, with a video control system we can perform a 100 % inspection of the barcodes to exclude the occurrence of duplicates or illegible codes.

The serialized and personalized labels offer the best possible flexibility. This happens by using suitable special materials of leading manufacturers, individual die-cutting forms and premium adhesives.

The labels can be inscribed directly as required in variable amounts with current data at the site, by that the storage and the management of numerous labels may be reduced or dropped.

Some materials and products to be labeled are still hot when the labels must be adhered. Additionally, other products can have a very rough or dirty or oily surface, which can be safely labeled with matching adhesives.

Our upscale and accurate processing with most modern die-cutting technologies guarantees the highest precision and reliability for the label application. Thus even serialized labels with adhesives which are difficult to process can be processed mechanically very well, which increases the user efficiency in the long term.

Frequently Asked Questions

Industrial applications of serialized and personalized labels

Especially the logistic processes, the manufacturing and the labeling of goods cannot be imagined without the labels with variable data as a carrier of information.

The typical labeling products are serialized type plates and warnings, inventory labels and logistic labels.

These labels can be used for example in the following sectors and areas with the goal of tracking and manufacturer’s proof of origin:

- Medical technology (unique device identification)

- Healthcare (labels for the identification of patients and specimen)

- Mechanical engineering (engines, machines and machine tools)

- Electric tools engineering (tools, home appliances, office machines etc.)

- Car manufacturing (OEMs, supplier)

- Vehicle construction (public transport, freight transport, ships and train construction)

- Chemical industry (tubes, lines and open sea identification)

Individual features of labels with consecutive serial numbers

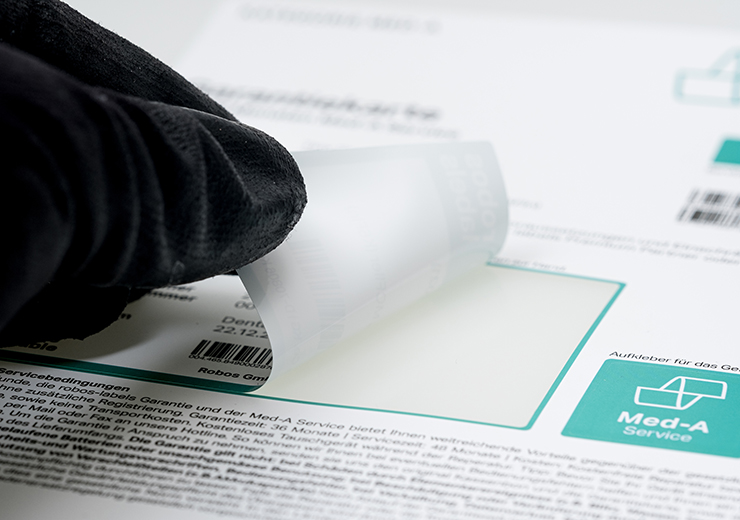

On a small self-adhesive label the item numbers, expiry dates, national refund numbers or badge numbers can be saved. They serve for example the control of commodity flow or the inventory. Furthermore, the intern company processes will be optimized with code labels or the product service contracts can be tracked and/or verified by stickers.

Technical key data of our labels with serialization or personalization

- Temperature resistance from +300° C (572° F) C to -196° C (-320.8° F)

- UV- and weather resistant foils up to max. 12 years

- Very thin (min. 6µ) as well as very thick (175µ) combinations of foils possible

- High-performance materials made of acrylate foil, polyimide foil, aluminum foil, and polyester (PET)

- Permanent adhesives with a very good adhesive power for high- and low-energy substrates

- Diverse carrier materials like compressed kraft paper in different thicknesses, transparent plastic liner, kraft paper siliconized on both sides, and environmentally stable kraft paper available

- Subsequently inscribable with thermal transfer printing method

- Foil features from soft and smooth and flexible to stable and tear-proof

Certifications

As a manufacturer robos-labels has a wide range of already approved and certified labeling solutions. When additional customized licenses are required, we can take on the approval- and certification process if desired.

We also cover the first article inspections (PPF, production process and product release) in accordance with the specifications of German Association of the Automotive Industry (VDA) as well as the American counterpart, a PPAP inspection (Production Part Approval Process) of the AIAG (Automotive Industry Action Group).

We already meet the following standards and regulations with our raw materials:

- FORD WSS-M99P41-A72

- MS-13445 (FCA – Fiat Chrysler Automobiles)

- TL 52038 (Volkswagen standard)

- GMW14573 (General Motors)

- TM-0030T-Y (Tesla)

- GS 97058 (BMW)

- MS 373-12 (Hyundai)

- DBL 8230 (Mercedes-Benz)

- TSM7508G (Toyota)

- UL969A:2020 Standard for Marking and Labeling Systems – Flag Labels, Flag Tags, Wrap-Around-Labels and Related Products

- UL817 Safety cord sets and power supply cords

- UL2238 Cable assemblies and fittings for industrial control and signal distribution

- UL94 Flammability of plastic materials for parts in devices and appliances (UL VTM-0 strictest classification)

- FMVSS 302 Evaluation of the flammability of interior materials (flammability/burn rate)

- REACH, RoHS and IMDS conformity

- ADR 2021 Ordinance on the transport of dangerous goods by road, rail and inland waterways (GGVSEB)

- CLP Regulation (Classification, Labelling and Packaging, in accordance with EC No. 1272/2008)

- BS 5609 Label resistance to saline sea water

- DIN EN ISO 11683:1997-11 Packaging — Tactile warnings of danger — Requirements

- FDA 175.105 INDIRECT FOOD ADDITIVES: ADHESIVES AND COMPONENTS OF COATINGS