Palpable elements – not only for visually handicapped people

There are 1.1 billion visually impaired people worldwide; 43 million of them are blind. Labels with palpable elements allow for the perception of braille texts and raised symbols.

In action everywhere

Tactile elements are necessary in many areas. The braille fonts and warning symbols are especially recognizable in pharmacy, where they label nasal sprays, eye drops, and medication for visually handicapped people. Furthermore, also in chemical industry you can find palpable warning triangles on detergents, fertilizers, and many other products. In transportation they serve the labeling of hazardous materials, and in plant construction the braille fonts appear on guidance systems, intercoms, on elevators, and in the construction of automatic machines. Also in the labeling of busses, trains, and ships the palpable information is useful and sometimes indispensable.

The haptic elements can additionally offer a decorative function for the refinement of products and will be manufactured according to the same principles like warning and braille labels. As a regular point grid, the palpable elements can not only look chic, but also provide for more grip, like for example on the battery labeling of a brand manufacturer for electric tools. This way not only important content can be transported, but also the attention of users can be increased.

Warning signs are mandatory

Products which are marked as very toxic, toxic, corrosive, harmful for health, highly flammable or combustible in accordance with Directive 1999/45/EC, must be additionally equipped with a tactile warning sign in accordance with ISO 11683.

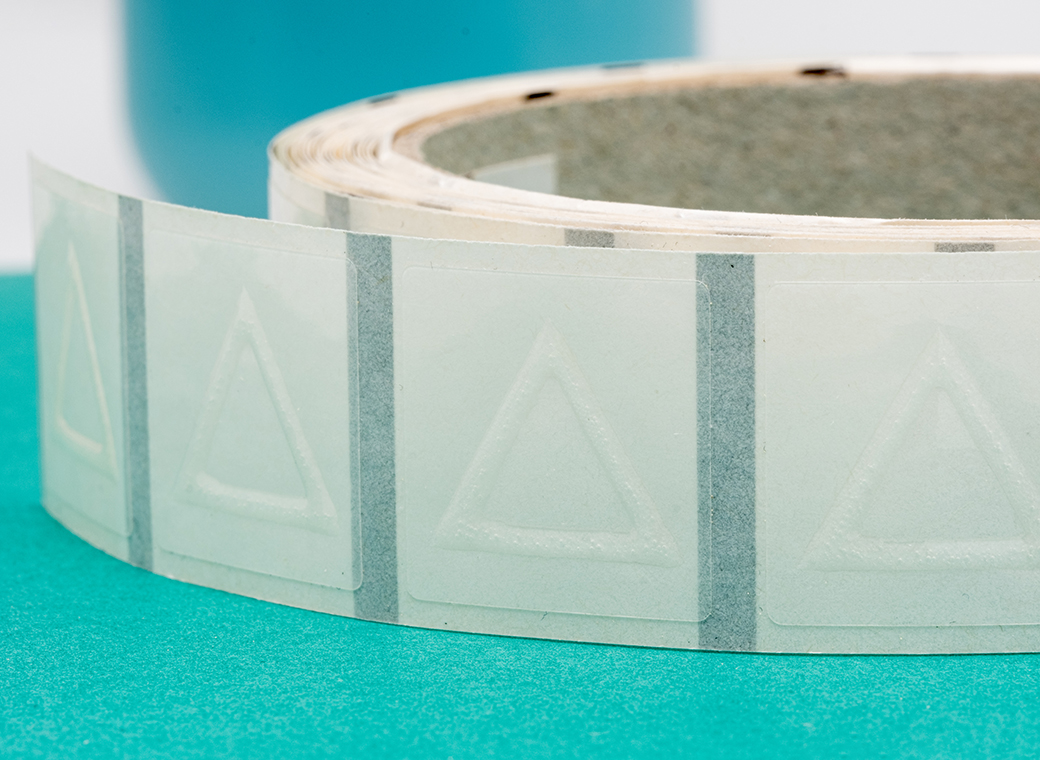

The palpable elements can be printed on the packaging directly or they will be printed on the self-adhesive and transparent label, which will be subsequently applied on the finished product. They are highly resistant in contact with chemicals and solvents and have a high abrasion resistance. They adhere reliably to difficult substrates as well.

The legibility is in details

Especially the sufficient height of the triangular structures is important for visually handicapped people. Also the size of symbols must correspond with legal regulations and the label must be placed in the right spot of the product. There shall be no be other embossed signs near the warning triangle that could cause confusion. The labeling with a warning sign must not detach and shall be applied without any air inclusion, so that these additional elevations do not irritate.

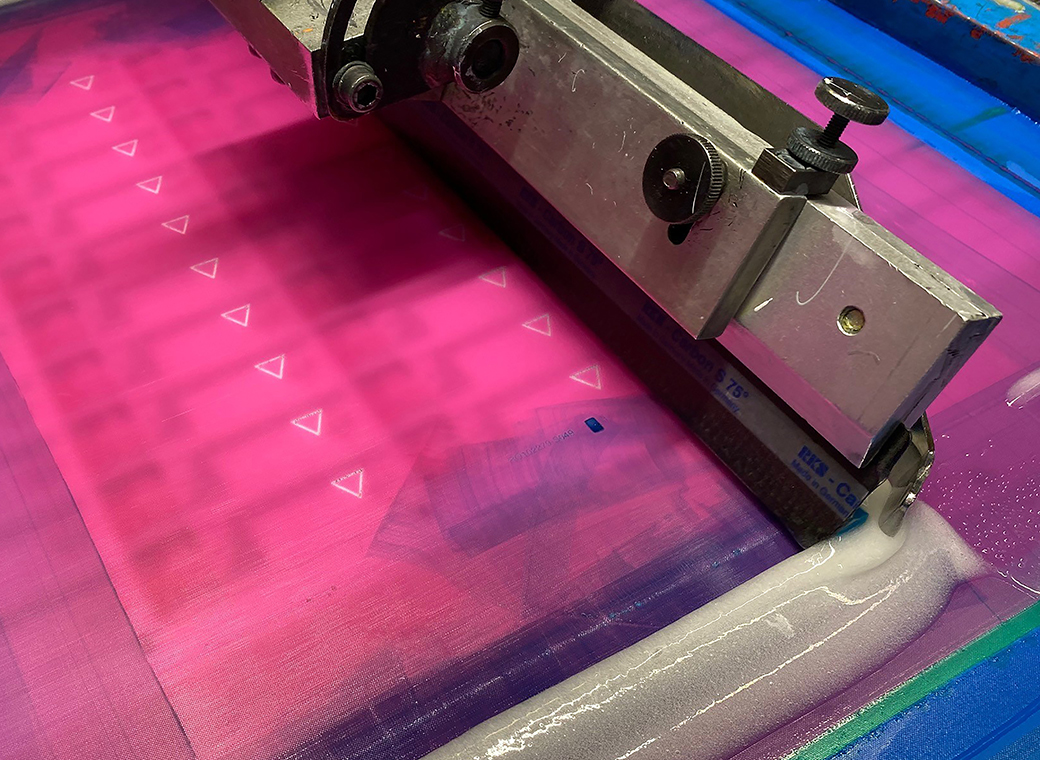

Palpable elements in silkscreen printing

The elevated design elements will be produced in silkscreen printing with a relief lacquer. This lacquer is a high-build and thus tangible UV contour lacquer layer, which can be glossy and matte in case it will be used as an optical refinement. As an alternative to the blind stamping, the relief lacquer offers the advantage that the back side of the printing substrate will not be deformed and hence remains free for designing. Relief lacquers are only suitable for 1-sided coatings.

For the printing a coarse screen tissue will be used, which allows the viscous lacquer to pass through. The whole height of the palpable print must be produced in one printing pass, because a further precisely fitting printing pass is impossible. The lacquer would flow off to the side from the element printed first. The drying and curing are carried out under UV light.

Die-cutting of tactile labels

Compared to usual labels, the labels are higher due to the thick lacquer application. Hence the cutter outlines must be higher for die-cutting, which is why a higher gap size for tools is necessary.

The labels are usually made of PE- or PVC foil. These cannot be processed with a laser die-cutter, because PE would melt and PVC would release toxic fumes due to the high temperatures. Only tactile labels made of paper can be die-cut with a laser die-cutter.

Possibilities and limits of the relief lacquer

Thinner and glossy painted papers are only applicable after a technical clarification. The detail resolution is limited – negative fonts are impossible. For larger areas the relief effect is extremely limited and the edges appear bulging due to the printing shoulder. A bubbling can impair the resolution and the three-dimensional relief effect.

On the white substrate the relief lacquer layer has a yellow-grayish coloring, furthermore, the flexibility of the viscous lacquer layer is limited. The lacquer motif must be placed outside of cutting, creasing and punching lines. The load on the labels due to mechanical pressure and their own weight can lead to the pressing in of the lacquer layer into the printing substrate, whereby the desired effect can be lost. For that reason during every processing step, like e.g. printing, cutting, packing, storing and during the transport any stress on labels must be avoided.

Conclusion

The manufacturing of tactile labels with silkscreen printing is a comparably convenient option to produce raised, legible or decorative elements. When all technical specifications and experience will be considered in the construction and production, these labels are functionally applicable and refine every product in a palpable and visible way.

Press contact:

Christine Hartmann

Marketing & communication

christine.hartmann@robos-labels.com

phone +49 (0) 7154 8225-58