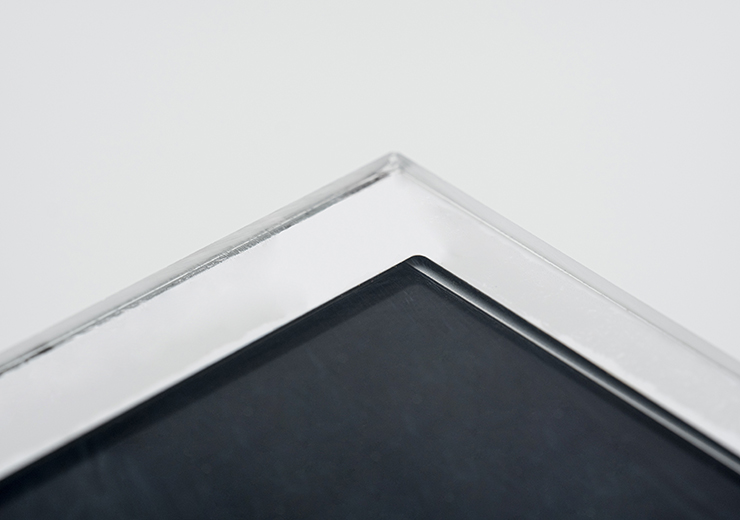

Connecting elements (adhesive frames)

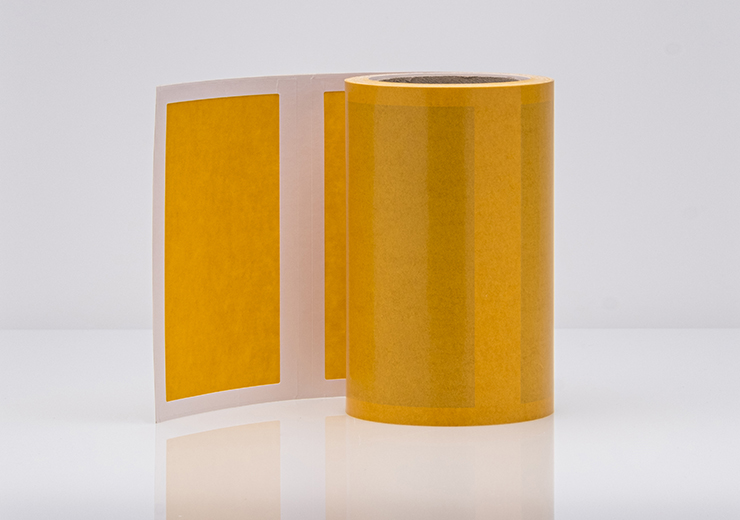

The labels can take on a variety of functions. Thus also the task of a connecting element or of a so‑called adhesive frame. These special labels are blanked parts which are tailored exactly to the respective customer product form and are equipped with an adhesive on both sides. This allows for a possibility to conglutinate and to connect parts instead of screwing or riveting. Thus the label, which is adhesive on both sides, will be adhered as a perfectly fitting frame e.g. to moldings or displays. The second adhesive side will be protected by a special cover paper until the part will be installed finally. Additionally, the used transfer adhesives can have variable thicknesses, e.g. to absorb vibrations or to be able to compensate the height tolerances of the housing parts.

These blanked parts will be manufactured from transfer adhesives and special mono-materials and foils and prevalently serve to the sealing, insulation (also noise minimizing), isolation and connection. These precise and special multifunctional labels will be especially applied in automotive, mechanical and electronical industries.

The main features of robos-labels adhesive frames are:

- Safe and long-term connection of parts and component groups

- Manifold protection of parts in the production and damping function

- Noise minimization and isolation of thermal bridges

- Height- and pressure compensation

- Sealing of parts openings (temporary or in the long term)

- Simplification of manufacturing processes due to the automation of material and product flow

- Replacement of mechanical connections

- Clean processing without additional tools and setting time

- High resistance outdoors and against chemicals and solvents

- Very high adhesive power also on difficult substrates (wide-ranged and upscale assortment available from stock)

The precisely fitting connection elements by robos-labels offer the best possible flexibility and will be adjusted individually to the customer’s requirements. This happens by using suitable special materials of leading manufacturers, individual die-cutting forms and premium adhesives.

Our upscale and accurate processing with most modern die-cutting technologies guarantees the highest precision and reliability for the label application. Thus even blanked parts with adhesives which are difficult to process can be processed mechanically very well, which increases the user efficiency in the long term.

Frequently Asked Questions

Industrial applications of connective elements and adhesive frames

The typical products are connective elements of parts and component groups, which in addition to the sealing also shall take on further functions like e.g. insulation and isolation and will be applied in the following braches and areas:

- Automotive industry (OEMs, supplier)

- Vehicle construction (public transport, freight transport, ships and train construction)

- Mechanical engineering (displays, frames, etc.)

- Electronic appliances (infotainment systems, speakerphones)

- Electric tools engineering (tools, home appliances, office machines)

- Industrial facilities (louvers, covers)

- Medical products (medical devices with monitoring and measuring functions, non-active products)

Individual specificity of the precisely fitting connective elements

Also pull-off tabs, application aids and complex custom blanking are possible.

Technical key data

- Temperature resistance from +150° C (302° F) C to -30° C (-22° F)

- Excellent resistance against UV beams, solvents, chemicals, humidity, and temperature load

- Very thin (min. 20µ) as well as very thick (400µ) combinations of foils possible

- High-performance materials made of acrylate foil, polyimide foil und polyester (PET)

- Permanent adhesives with a very good adhesive power for high- and low-energy substrates

- Diverse carrier materials like compressed kraft paper in different thicknesses, transparent plastic liner, kraft paper siliconized on both sides, and environmentally stable kraft paper available

- Foil features from soft and smooth and flexible to stable and tear-proof

Certifications

As a manufacturer robos-labels has a wide range of already approved and certified labeling solutions.

When additional customized licenses are required, we can take on the approval- and certification process if desired.

We also cover the first article inspections (PPF, production process and product release) in accordance with the specifications of German Association of the Automotive Industry (VDA) as well as the American counterpart, a PPAP inspection (Production Part Approval Process) of the AIAG (Automotive Industry Action Group).

We already meet the following standards and regulations with our raw materials:

- UL969A:2020 Standard for Marking and Labeling Systems – Flag Labels, Flag Tags, Wrap-Around-Labels and Related Products

- UL817 Safety cord sets and power supply cords

- UL2238 Cable assemblies and fittings for industrial control and signal distribution

- UL94 Flammability of plastic materials for parts in devices and appliances (UL VTM-0 strictest classification)

- FMVSS 302 Evaluation of the flammability of interior materials (flammability/burn rate)

- FORD WSS-M99P41-A72

- MS-13445 (FCA – Fiat Chrysler Automobiles)

- TL 52038 (Volkswagen standard)

- GMW14573 (General Motors)

- TM-0030T-Y (Tesla)

- GS 97058 (BMW)

- MS 373-12 (Hyundai)

- DBL 8230 (Mercedes-Benz)

- TSM7508G (Toyota)

- REACH, RoHS and IMDS conformity

- ADR 2021 Ordinance on the transport of dangerous goods by road, rail and inland waterways (GGVSEB)

- CLP Regulation (Classification, Labelling and Packaging, in accordance with EC No. 1272/2008)

- BS 5609 Label resistance to saline sea water

- DIN EN ISO 11683:1997-11 Packaging — Tactile warnings of danger — Requirements

- FDA 175.105 INDIRECT FOOD ADDITIVES: ADHESIVES AND COMPONENTS OF COATINGS