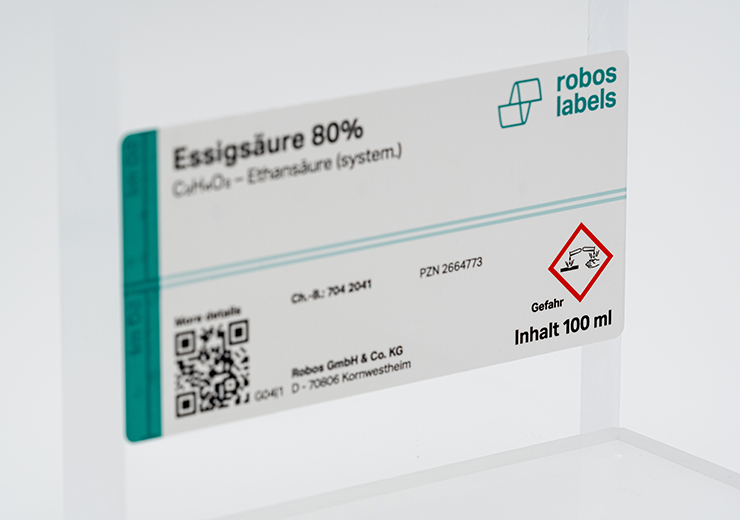

Double-sided readable labels for adhesion on transparent surfaces

In the field of public transportation, buildings and institutions the areas are often separated by glass elements. Thus, due to the high public frequency, e.g. information and safety cautions must be permanently good legible from both sides. The so‑called behind‑glass labels are perfectly suitable for that and will be adhered to the glass pane. Due to the double‑sided imprint the information is visible and legible from both sides.

The key features of the double‑sided printed behind‑glass labels

- UV stable adhesive, which yellows barely visible

- High opacity between both printed images, which minimizes the shadow effects

- Variable data can be imprinted, which makes further information retrievable online

- Labels can be delivered rolled or sheeted

- Very high adhesive power of the labels for a labeling in the long term

- Numerous special materials by Avery, 3M, Flexcon, and Tesa are available from stock

- Behind‑glass labels in individual formats and special forms

Functions and advantages – precisely tailored to your requirements for the labeling

The behind‑glass labels offer the best possible flexibility and will be adjusted individually to the customer’s requirements. This happens by using suitable special materials of leading manufacturers, individual die‑cutting forms and premium adhesives. The double-sided readable labels are usually adhered on panes in vehicles of the local public transportation, administrative buildings or congress centers. Thus they show high resistance against repeating cleaning processes and in contact with chemicals (disinfection) and solvents.

Our upscale and accurate processing with most modern die‑cutting technologies guarantees the highest precision and reliability for the label application.

Frequently Asked Questions

Industrial applications of double sided readable labels

The advantage of the behind‑glass labeling is that the label is protected against outdoor impacts like weather and dirt on the one hand, and on the other hand it can be less manipulated. A typical application area is glass panes and glass doors in busses and trains as well as glass cabinets and shop windows. Often the indications of the rules of conduct, the video surveillance, and the alarm systems are depicted.

These product solutions will be applied for example in the following branches and areas:

- Mechanical engineering (warnings on the control windows of machine housing etc.)

- Car manufacturing (assembly instructions on glass components etc.)

- Vehicle construction (glass panes for tractors, construction machinery, passenger transport, ship and train construction)

- Medical technology (warnings on laboratory facilities)

- Trade, medical and other offices (sanitary protection glass)

- Building sector (window glasses and glass door panels)

Individual features of double-sided readable labels

The labels are characterized by a print also on the side with adhesive and thus the information can be displayed on both sides.

Technical key data of our double-sided readable labels

- Temperature resistance from +120° C (248° F) C up to -40° C (-40° F)

- UV and weather resistant foils and color up to max. 10 years

- Very thin (min. 6µ) as well as very thick (175µ) combinations of foils possible

- High-performance materials made of PVC (polyvinylchloride) and PE (polyethylene)

- Permanent adhesives with a very good adhesive power for high-energy substrates

- Diverse carrier materials like compressed kraft paper in different thicknesses, transparent plastic liner, kraft paper siliconized on both sides, and environmentally stable kraft paper available

- Available rolled or sheeted

Certifications of our double-sided readable labels

As a manufacturer robos-labels has a wide range of already approved and certified labeling solutions. When additional customized licenses are required, we can take on the approval- and certification process if desired.

We already meet the following standards and regulations with our raw materials:

- UL969 Marking and labeling systems (labels on smooth and not convex surfaces)

- UL817 Safety cord sets and power supply cords

- UL2238 Cable assemblies and fittings for industrial control and signal distribution

- UL94 Flammability of plastic materials for parts in devices and appliances (UL VTM-0 strictest classification)

- FMVSS 302 Evaluation of the flammability of interior materials (flammability/burn rate)

- REACH, RoHS and IMDS conformity

- ADR 2021 Ordinance on the transport of dangerous goods by road, rail and inland waterways (GGVSEB)

- CLP Regulation (Classification, Labelling and Packaging, in accordance with EC No. 1272/2008)

- BS 5609 Label resistance to saline sea water

- DIN EN ISO 11683:1997-11 Packaging – Tactile warnings of danger – Requirements

- FDA 175.105 INDIRECT FOOD ADDITIVES: ADHESIVES AND COMPONENTS OF COATINGS